A new analysis states that Britain needs to expand the installation of public charge points from 27 per day to 50 if it aims to meet the demand for electric vehicles before the prohibition on new gasoline, diesel, and hybrid vehicle sales takes effect.

According to New AutoMotive, there are now roughly 24,000 public chargers, with at least 230,000 needed by 2035 if motorists are to have convenient access to plugging in their zero-emission vehicles.

It cautions that the government's green goals could be jeopardised if chargers aren't ramped up quickly enough to match the growing demand for electric vehicles, although the ban on new internal combustion engines is still eight years awa. According to New AutoMotive, between 230,000 and 280,000 public charging stations would be required by 2030.

Mike Hawes, chief executive at the Society of Motor Manufacturers and Traders claimed that the UK is already experiencing “rocketing uptake of plug-in vehicles” but warned:

“To meet our collective decarbonisation ambitions, we need to ensure all drivers can make the switch – not just those with private driveways – requiring a massive investment in public recharging infrastructure”.

With a prohibition on new petrol and diesel automobiles slated to go into effect in 2030 and a later deadline for hybrid vehicles in 2035, EV adoption is expected to skyrocket in the coming years. Automakers may soon be required to sell a growing number of electric vehicles each year to accelerate the transition.

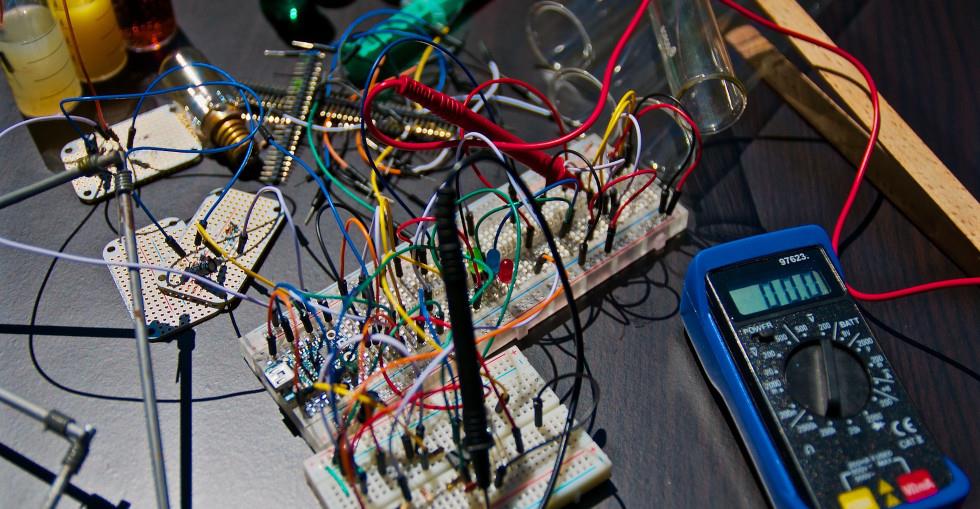

However, an increase in electric charging points is not the only result of the new diesel and petrol car ban. This heavy reliance on electrical engineering could portent that the electronics industry, specifically those who specialise in printed circuit boards (PCB), should begin to gear up.

In an attempt to reduce CO2 emissions and protect the environment, moving to electric vehicles poses new, lucrative opportunities for PCB design and production, which will begin to play a more senior role in manufacturing modes of transport.

Newbury-based PCB production company, Garner Osborne, suggests that the increase in PCM demand is positive news for industry owners,

“An increase in PCB demand should, by the laws of economics, reduce prices of components and boards as demands increase the opportunity for companies to take advantage of economies of scale”.

However, with demand comes disadvantages. An increase in PCB production will result in an increase in copper production. This will result in significant pressure on the copper industry, which is expecting to see skyrocketing demands by 2027.

Nonetheless, the UK automotive industry and PCB industry will be at the forefront of the transition to net zero.